Technology

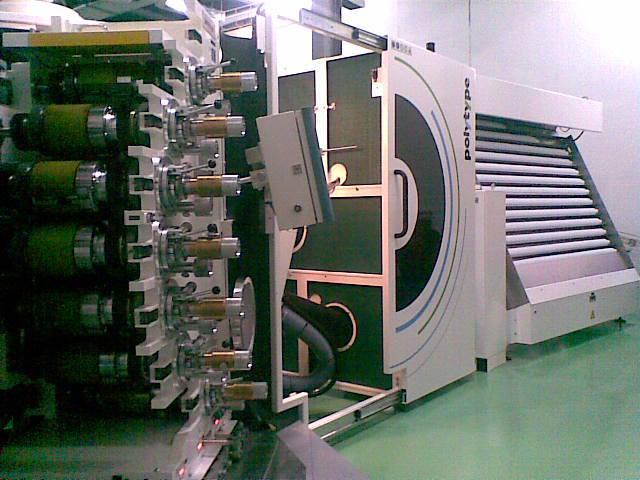

Extrusion of PP, PS foils

Plastic extrusion is a process of manufacturing a large volume of raw plastic that dissolves and shapes into a continuous profile and obtains a plastic glass.

Extrusion also produces items such as: pipes, gaskets, fences, transverse fences, window frames, plastic foils and moldings, thermoplastic films and wire insulation.

This procedure begins by adding plastic materials (beads, granules or flakes) from the funnel into the extrusion tube.

The material was gradually discharged by the mechanical energy obtained by turning the bolts and heaters arranged along the pipes.

The molten polymer thus formed is molded in a tube molded form cured during cooling.

Thermoforming

Offset printing